0.22 μm Hydrophilic Sterile PVDF Syringe Filters for Mycoplasma Filtration Individually Packed

4.9/5 Based on 723+ Verified Reviews

Cofilters offers sterile PVDF syringe filters in both single-layer and double-layer configurations, with double-layer filters featuring a prefilter for high throughput and prevention of back pressure. These filters utilize a hydrophilic PVDF membrane ensuring low protein binding and fast flow rates, making them ideal for applications requiring high protein recovery.

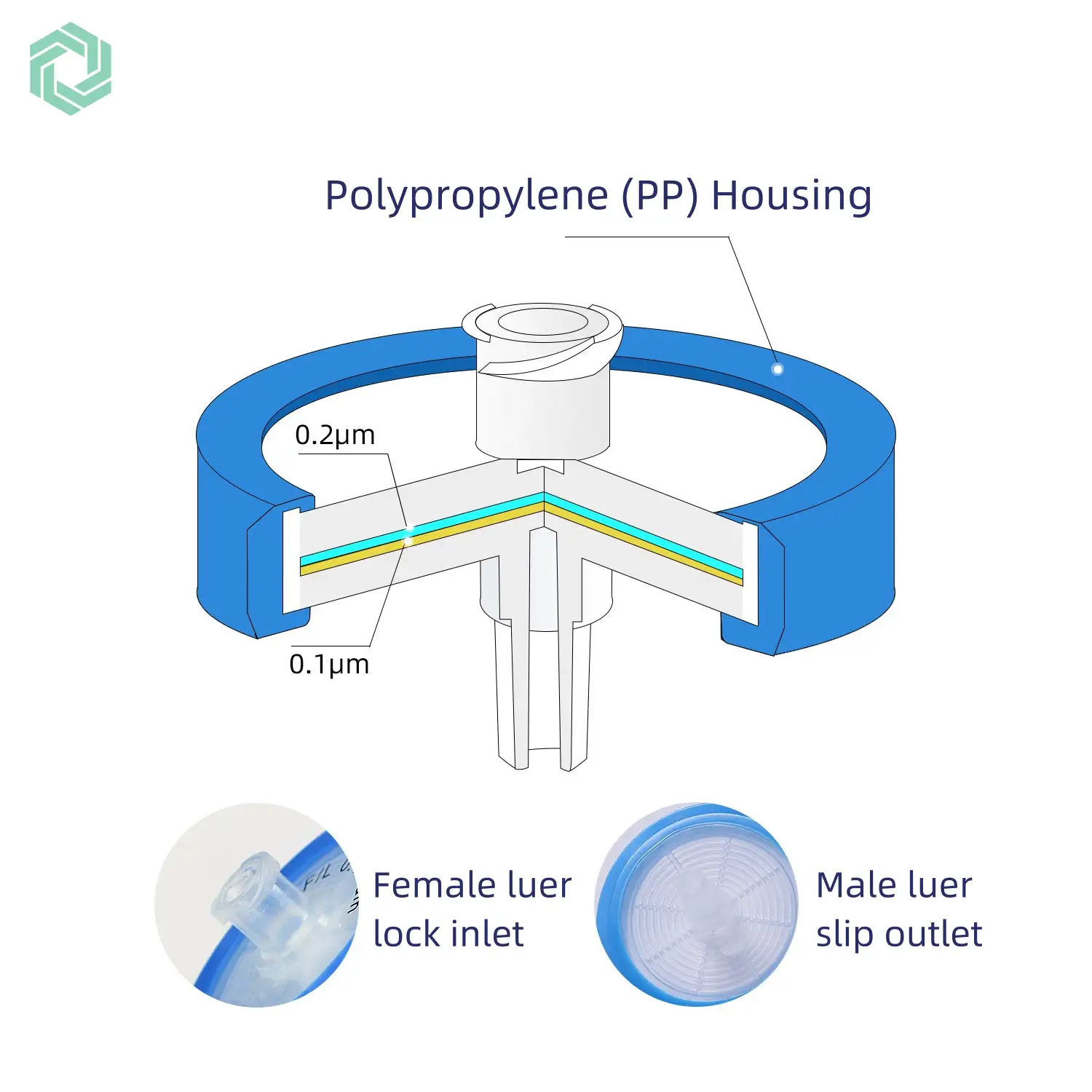

- Premium Polypropylene PP housing

- Syringe filters diameter available 13, 25 and 33 mm

- Double-layer membrane pore size: 0.22 μm or 0.45 μm

- Color-coded outer ring identified the membrane for filter media type.

Low extractables, low binding

0.22 Micron Hydrophilic Sterile PVDF Syringe Filters

The 0.22 micron Polyvinylidene difluoride (PVDF) membrane undergoes a hydrophilic treatment, enabling it to achieve both low protein binding and rapid flow rates concurrently, ideal for scenarios requiring high protein recovery. Suited for filtering protein solutions as well as mild organic biological solutions or enzyme solution.

Sterile 100%

Sterilized by gamma radiation individually single blister packed, RNase & Dnase free

Efficiency pre-filter

Single or double-layer hydrophilic PVDF membranes Endotoxin<0.25 EU/mL, pH range 2-10

Stable Connections

Premium Polypropylene(PP) Housing , luer lock inlet/outlet slip offers a leak-tight syringe

Applications

Syringe filters can satisfy the requirements of life science applications for sterilization of solutions or clarification of biological fluids.

- Filtration chromatography samples, buffers, or mobile phases

- Sterilization enzyme/protein solutions, nutrient media for cell/tissue cultures, and biological fluids

- Clarification protein immunoassay samples and associated buffers for western blotting

- Clarification nucleic acid hybridization samples and associated buffers for blotting

How to select the right Sterile PVDF Syringe Filters by sample liquid volume?

| Sample Volume | Filter Diameter | Filtration Area | Holdup Volume | Throughput Volume |

|---|---|---|---|---|

| < 10 ML | 13 mm | 0.92 cm² | < 25 μl | < 25 ML |

| 10-100 ML | 25 mm | 3.4 cm² | < 100 μl | < 100 ML |

| 100-200 ML | 33 mm | 4.9 cm² | < 125 μl | < 125 ML |

How to use a syringe filtration?

Selecting the appropriate membrane material depends on your sample’s characteristics. Ensure chemical compatibility to prevent extractables and leachables. Check out this article for more insights.

Load test sample into syringe

Find right lab syringe filters

Attach the filters twist securely

Push sample through the filter

Frequently Asked Questions

What is the filtration area of syringe filter?

Visit the product page of your syringe filter and click on the “Application/Specification” tab located in the middle. Scroll down to find the filter area. For any assistance, reach out to sales@cofilters.com.

How do you assure the sterile syringe filters sterilized?

Our standard Cofilters sterile syringe filters undergo sterilization through gamma irradiation. We carefully control the irradiation level to guarantee sterility. Each lot is tested with spore strips to ensure effectiveness before sale.

Does the sterile syringe filter have a prefilter?

Our sterile syringe filters feature a dual-layer membrane design. The top layer, with a larger pore size of 0.65μm, acts as a prefilter, followed by a 0.22μm layer for sterilization.

Are syringe filters from different suppliers equivalent?

Syringe filters with absolute rated membrane media are generally expected to be similar across suppliers if they share the same size, membrane material, and pore size rating. However, this consistency isn’t guaranteed for filters with nominally rated media like glass fiber or nonwoven polypropylene. When exploring different suppliers for nominally rated syringe filters, pore size rating alone isn’t sufficient for comparison. It’s essential to carefully review the media specifications provided by the supplier to make an informed selection.

Do you provide certificates of conformance (CoC) with syringe filter orders?

Certainly, certificates of conformance (CoC) are available with syringe filter orders upon request. Remember to ask for the certificate when placing your order.

What is the maximum operating temperature for the Cofilters syringe filters?

The syringe filters have a maximum recommended operating temperature of 60°C when used with compatible fluids. Operating at higher temperatures can weaken the housing strength, potentially requiring a limit on applied pressure. Ensure to take appropriate safety measures, including wearing personal protective equipment (PPE), when handling hot fluids.

Got a filtration question you need solving?

Whether it’s about finding the right filter for your application or tackling a tricky science problem, I’m here to help you turn your ideas into reality. Let’s conquer those big science challenges together!